Original German WWII Extra Large M35 Single Decal Army Heer Helmet with 60cm Liner – NS68 Original Items

$ 1.395,00 $ 348,75

Original Item: Only One Available. This is a nice service worn condition all original example Extra Large Size Model 1935 German WW2 helmet with a single Heer decal. This stamped sheet steel construction helmet retains 85% of the original paint and is in very good condition overall. The left side of the helmet features a very nice Army decal. The decal is retained at about 85%.

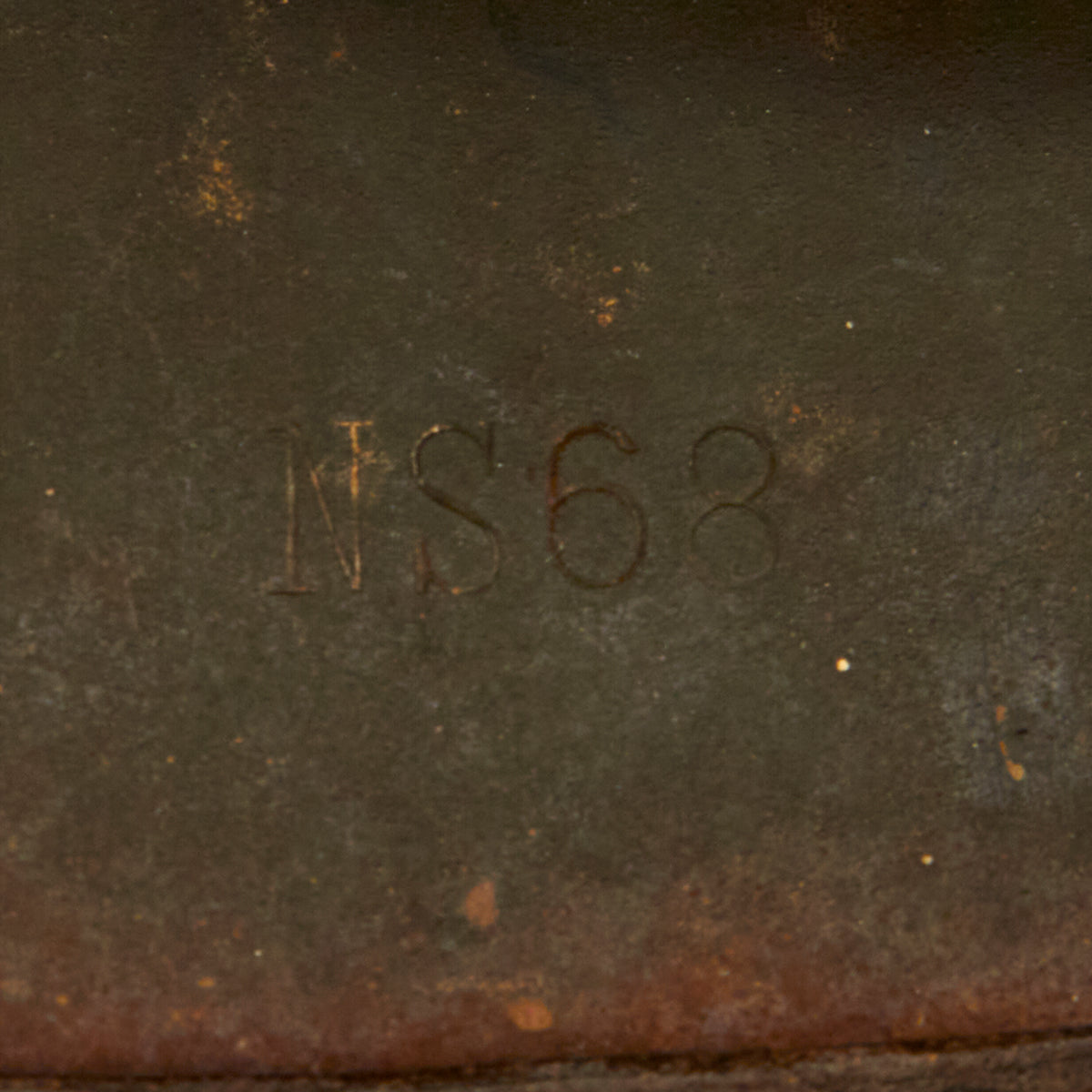

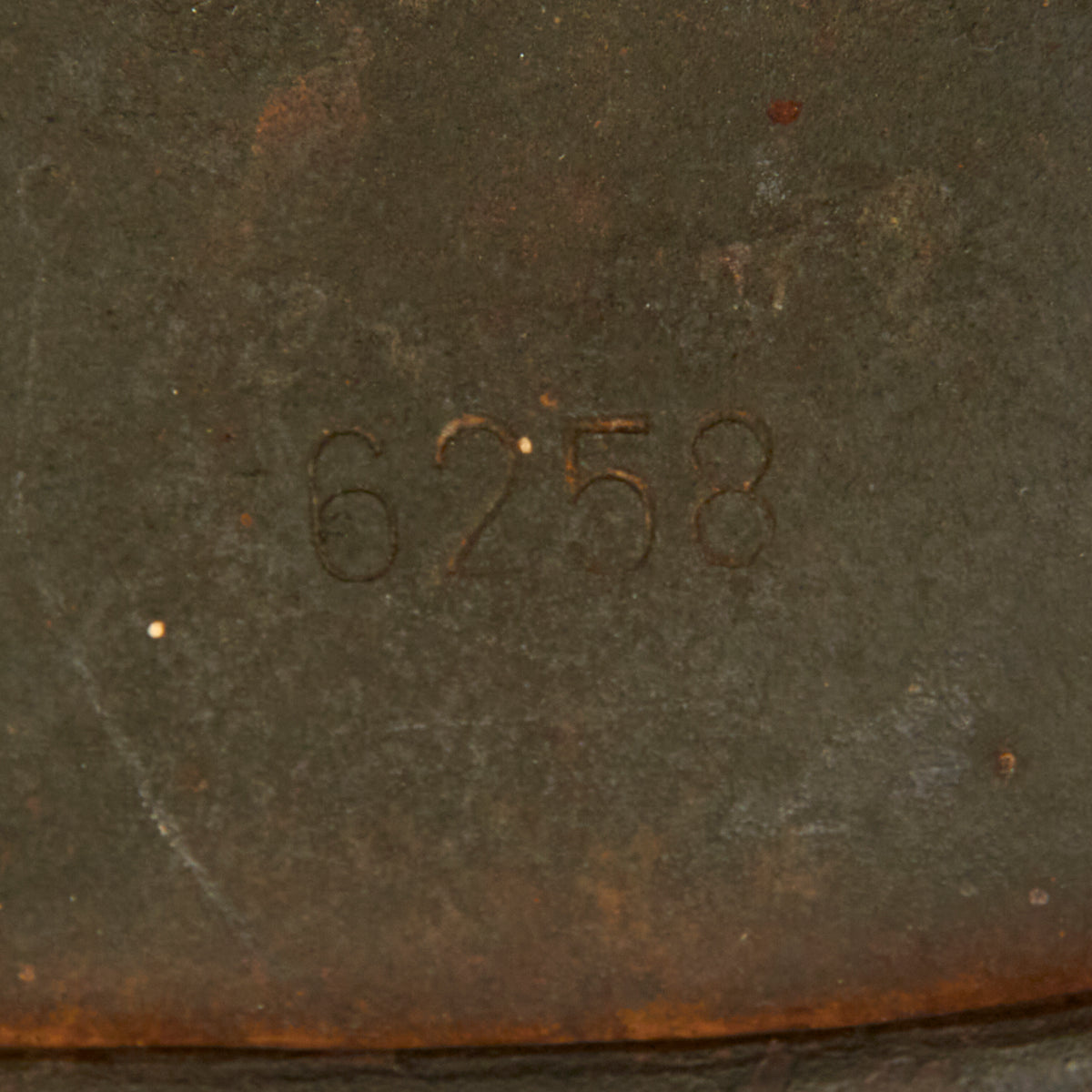

The reverse, interior, neck guard apron is serial number stamped, 6258 and the interior, left side, apron has a stamped manufacturer’s code and size, NS68 indicating that Vereinigte Deutsche Nikelwerke, of Schwerte, Germany manufactured it in size 68. Size 68 is a rare extra large size that can accommodate liners from 60cm to 61cm or US 7 1/2 to 7 5/8. Size 68 shells are the hardest to find and are therefore the most valuable to a collector.

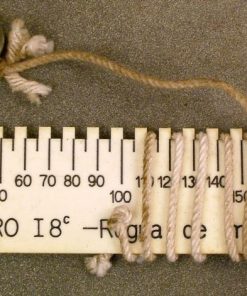

All three liner retaining pins are present, with most of there original paint intact. The interior of the helmet still has the original M31 leather liner. Even though all 8 fingers are still intact, the condition of the leather is poor and has dried out and shrunk a little from age and storage. The leather is cracked around the lip and throughout the rest. The mid war issue galvanized steel liner band is faintly marked on the left outer side with 68 nA / 60, indicating that the liner is a size 60, intended for a 68 shell. There appears to be manufacturer mark on the other side over the right ear, however the oxidation on the liner band makes it hard to read. We can see enough of it however to know that it reads:

SCHUBERTH-WERKE K.-G.

D. R. P.

1940

BRAUNSCHWEIG

Original chinstrap is also present and in fair condition but unfortunately is torn, now repaired with leather tape near the buckle.

Overall a very nice Extra Large Size M35 Single Decal Heer Army helmet, with loads of patina! M35 helmets of this quality are always the hardest to find on the market. This is an item that will only continue to appreciate in value over time.

The first “modern” steel helmets were introduced by the French army in early 1915 and were shortly followed by the British army later that year. With plans on the drawing board, experimental helmets in the field, (“Gaede” helmet), and some captured French and British helmets the German army began tests for their own steel helmet at the Kummersdorf Proving Grounds in November, and in the field in December 1915. An acceptable pattern was developed and approved and production began at Eisen-und Hüttenwerke, AG Thale/Harz, (Iron and Foundry Works), in the spring of 1916.

These first modern M16 helmets evolved into the M18 helmets by the end of WWI. The M16 and M18 helmets remained in usage through-out the Weimar Reichswehr, (National Defence Force, Circa 1919-1933), era and on into the early years of the Third Reich until the development of the smaller, lighter M35 style helmet in June 1935.

In 1934 tests began on an improved Stahlhelm, whose design was a development of World War I models. The Eisenhüttenwerke company of Thale carried out prototype design and testing, with Dr. Friedrich Schwerd once again taking a hand.

The new helmet was pressed from sheets of molybdenum steel in several stages. The size of the flared visor and skirt was reduced, and the large projecting lugs for the obsolete armor shield were eliminated. The ventilator holes were retained, but were set in smaller hollow rivets mounted to the helmet’s shell. The edges of the shell were rolled over, creating a smooth edge along the helmet. Finally, a completely new leather suspension, or liner, was incorporated that greatly improved the helmet’s safety, adjustability, and comfort for each wearer. These improvements made the new M1935 helmet lighter, more compact, and more comfortable to wear than the previous designs.

The Army’s Supreme Command officially accepted the new helmet on June 25, 1935 and it was intended to replace all other helmets in service.

More than 1 million M1935 helmets were manufactured in the first two years after its introduction, and millions more were produced until 1940 when the basic design and production methods were changed. This mainly involved adding the vent hole to the stamping process, as opposed to adding the rivet later.

Fast Shipping with Professional Packaging

Thanks to our longstanding association with UPS FedEx DHL, and other major international carriers, we are able to provide a range of shipping options. Our warehouse staff is expertly trained and will wrap your products according to our exact and precise specifications. Prior to shipping, your goods will be thoroughly examined and securely secured. We ship to thousands clients each day across multiple countries. This shows how we're dedicated to be the largest retailer on the internet. Warehouses and distribution centres can be located throughout Europe as well as the USA.

Note: Orders with more than one item will be assigned a processing date depending on the item.

Before shipping before shipping, we'll conduct a thorough inspection of the items you have ordered. Today, the majority of orders will be delivered within 48 hours. The delivery time will be between 3-7 days.

Returns

The stock is dynamic and we cannot completely manage it because multiple stakeholders are involved, including our factory and warehouse. So the actual stock may alter at any time. It's possible that you may not receive your order once the order has been made.

Our policy is valid for a period of 30 days. If you don't receive the product within 30 days, we are not able to issue a refund or an exchange.

You can only return an item if it is unused and in the same state as the day you received it. You must have the item in its original packaging.

Related products

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Angolan Rebel 1970s era 60mm Inert Display Mortar from Angolan Civil War Original Items

Uncategorized

Armored Burgonet Helmet & Polearm from Scottish Castle Leith Hall Circa 1700 Original Items

Uncategorized

Uncategorized

Uncategorized