Original British RML 2.5 inch Jointed Mountain Cannon- The Screw Gun Original Items

$ 32.995,00 $ 8.248,75

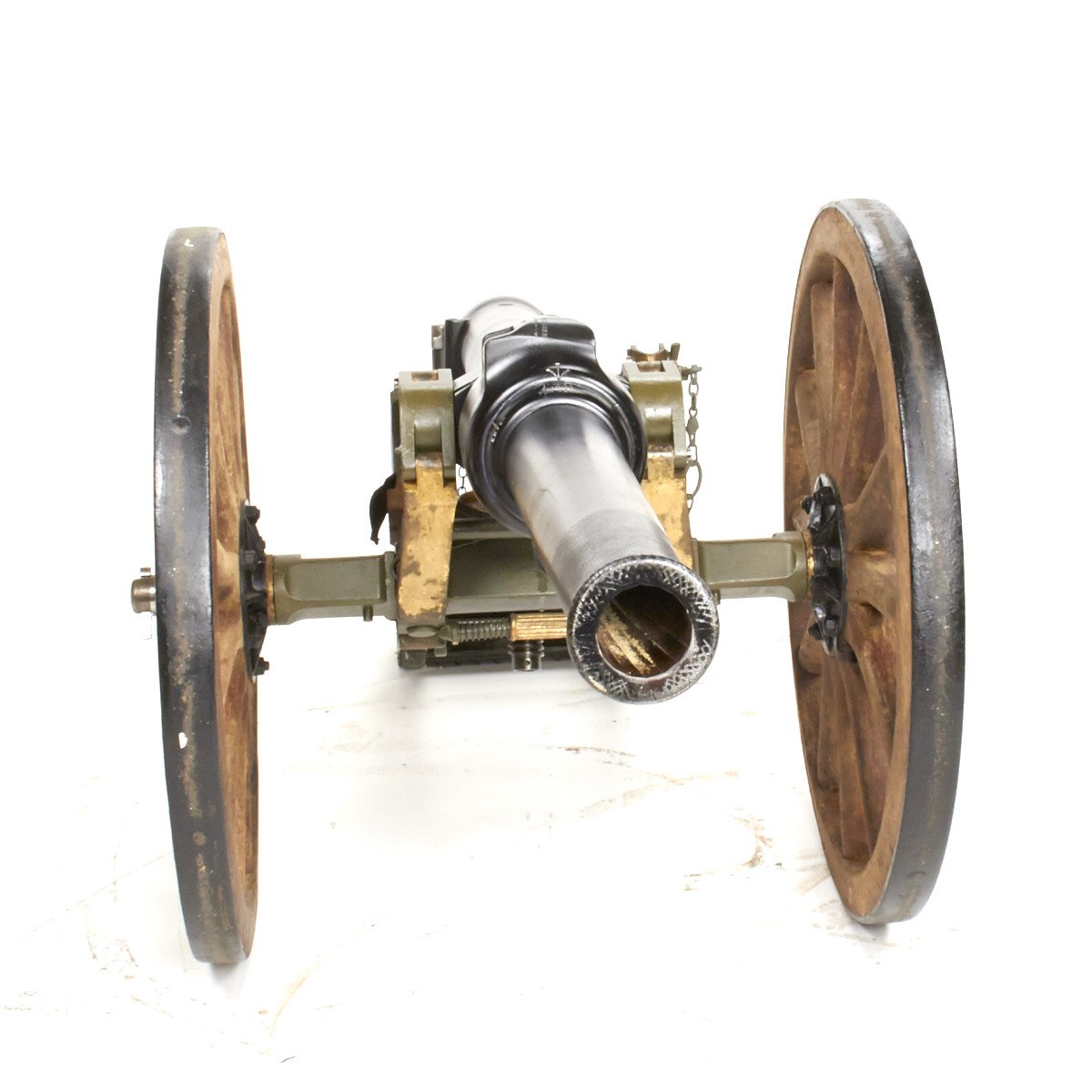

Original Item: Very Few Available. Antique mountain cannon, fully functional, not de-activated. Finally approved by the U.S. BATF as an unrestricted Antique; this is an exceptional, rare and very desirable British Empire “Screw Gun” dated 1902. The Screw Gun was a British development from the 1870s. An artillery piece was fitted with a two-part barrel that “screwed” together for use. The idea was to make such a substantial weapon transportable by mule train in mountainous regions.

It took a minimum of four mules to carry just the gun and mount. Two mules each to take half of the rifled barrel, one mule to carry the mount and a forth mule to carry the pair of 36″ spoke wheels. Additional pack animals were required to transport the ammunition, which consisted of bagged powder and separate studded projectiles with quill-fused primers. There has always been tremendous romance associated with these cannons of the Empire. The English storyteller and poet Rudyard Kipling even penned a lengthy poem dedicated to the Screw Gun. Transport by Freight Collect from IMA Warehouse (our mule caravan).

Every example in our inventory has been expertly cleaned, restored and painted by Curtis Wolf of Ordnance Research who has been involved in the firearms manufacturing field for more than 30 years. His work in restoring antique ordnance is world renowned as being second to none.

The Ordnance RML 2.5 inch mountain gun is a British rifled muzzle-loading mountain gun of the late 19th century designed to be broken down into four loads for carrying by man or mule. It was intended as a more powerful successor to the RML 7 pounder Mountain Gun. Some writers incorrectly refer to the 2.5 inch gun as a “7 pounder” because it also fired a shell of approximately 7 pounds, but its official nomenclature was 2.5 inch RML.

In 1877 Colonel Frederick Le Mesurier of the Royal Artillery proposed a gun in 2 parts which would be screwed together. The Elswick Ordnance Company made 12 Mk I guns based on his design and they were trialled in Afghanistan in 1879. Trials were successful and Mk II with some internal differences made by the Royal Gun Factory entered service.

The gun was a rifled muzzle-loader. Gun and carriage were designed to be broken down into their basic parts so they could be transported by pack animals (4 mules) or men. The barrel and breech were carried separately, and screwed together for action, hence the name “screw gun”.

The gun was used in the Second Boer War (18991902) on its standard mountain gun carriage, and also with the Natal Field Battery at Elandslaagte and Diamond Fields Artillery at Kimberley on field carriages which had larger wheels and gave greater mobility.

A major defect in the war was that the gun’s cartridges still used gunpowder as a propellant, despite the fact that smokeless cordite had been introduced in 1892. The gunpowder generated a white cloud on firing, and as the gun could only be aimed using direct line of sight, this made the gunners easy targets for Boer marksmen as the gun lacked a shield.

It proved to be ineffectual and outclassed by Boer ordnance and was replaced by the BL 10 pounder Mountain Gun from 1901.

Either 4 or 6 guns (sources appear imprecise) were returned to service from Southern African garrisons in 1916 and were employed by the Nyasaland-Rhodesian Field Force in the campaign in German East Africa. Writers who refer to “7 pounders” in WWI are in fact referring to this 2.5-inch (64 mm) gun.

Below is an article published by expert John Walter:

The Jointed Ordnance or Screw Gun has an interesting history in British service. Campaigns undertaken in excessively hilly or mountainous regionssuch as the North West Frontier or the Himalayan foothillswere often difficult to support effectively with conventional artillery. Field guns were too cumbersome and often too heavy to manoeuvre satisfactorily, and mortars, though readily portable, were essentially close-range weapons that conferred no real advantage in the mountains. The mountain gun promised to provide an effective compromise. The first mountain guns were short-barreled muzzle loaders, initially smooth-bore but then rifled. The need to keep weight down to a load suitable for a mule, generally reckoned to be about 200lb, ensured that the guns were comparatively small: the 7-pr Rifled Muzzle Loader, Steel, Mark III, Mountain Service weighed 150lb and was only a little over 29in long. Though portability was enhanced by the meagre dimensions, range and accuracy were correspondingly restricted. The search for something more effective ended in 1879, when a proposal by Colonel Le Mesurier was accepted and the 2.5-inch Rifled Muzzle Loader, Steel, Jointed, Mountain Service, Mark I was introduced. A 24oz charge of black powder gave a 7lb shell a muzzle velocity of about 1400 ft/secmuch greater than preceding designsand, as the bore was 66½in long compared with 24in, accuracy was also much better. The gun was made in two parts, secured by a loose trunnion ring or collar; ignition was achieved by a conventional touch-hole on top of the breech immediately ahead of the cascabel.

The carriage was small but comparatively conventional, with a fabricated wrought-iron body and spoked wood wheels with iron tyres. The body and the wheels each made one mule load. The efficiency of the 7-pr jointed muzzle loader was greatly appreciated, and it was made in quantity. However, rifled muzzle loaders were rapidly eclipsed by the introduction of quick-firers using self-contained metal cased ammunition, and experience with the 7-pr RML in the South African (Boer) War of 1899- 1902 was profoundly disappointing. Something better than the original jointed design was needed. The answer was found in an amalgamation of the basic twopart construction with the Frenchdesigned de Bange breech, which, patented in 1873, had been adopted by the Royal Navy in 1881. A hinge-piece or carrier attached to the standing breech supported a cylindrical block, cut with an interrupted screw, which could be rotated to engage the inside surface of the bore behind the chamber. A mushroom-headed spindle ran through the block to retain two expansion plates and a compressible pad or obturator made of asbestos fibres soaked in tallow within a cloth bag. When the gun was fired, the mushroom-head and spindle slid back, compressing the obturator between the expansion plates. This forced the edges of the pad out against the chamber wall, preventing the blow-by of propellant gas with surprisingly effectively. Despite the heat of combustion, the pad could withstand hundreds of shots. Its elasticity was sometimes reduced by rapid fire, but it could be removed, placed in a bucket of water, then replaced without loss of efficiency.

The breech-loading Screw Gun of 1903 was rated a 10-pounder, owing to the increase in the weight and length of the shell made possible by the new method of loading. It fired a bagged charge instead of a self-contained cartridge, and was firednot by percussion or even by electricitywith a quill or friction tube. The Quill, Friction, Mark IV had a body of quill about 2.75 inches long, filled with tube composition, and a roughened nib piece is fitted to pull out of the head, and is smeared with detonating composition. To support the head of the tube, and prevent it from being bent when the nib piece is withdrawn, a leather loop is fastened and woolded to the head with fine copper wire, and this also serves to secure the nib piece in its place A sharp pull on the lanyard [hooked into the nib piece] withdraws with the nib piece, exploding the detonating composition, and firing the composition in the tube, which flashes down the vent and ignites the cartridge in the gun. This method of ignition, developed by Colonel Edward Boxer of the Royal Laboratory in 1862, was exceptionally primitive for an essentially late-Victorian design. The 7-pr jointed muzzle-loading mountain gun could be fired as long as loose powder was available to serve as priming, but the 10-pr could not be used unless friction igniters were to hand: the lengthy axial vent running through the breech-block made conventional touchhole ignition impossible, making the breech-loading mountain gun potentially less effective as a weapon as Nelsons shipboard cannon at Trafalgar!

The carriage of the 10-pr jointed gun combined a conventional boxtype iron trail weighingat least on the example pictured here2 cwt. 2 qtrs. 17 lb. (297lb), including the detachable axle tree, with woodspoke iron-tyred wheels of 1 cwt. 1 qtr. 24 lb. (164lb). This was judged to provide two one-mule loads. A third mule carried the axle tree and the elevating gear, which together weighed about 120lb, and a variety of stores.

The barrel, which provided two more mule loads, was assembled by screwing the chase to the breech (with the assistance of a crank) until the locating marks aligned satisfactorily. Marks on the components show the direction of motion and the limits of engagement. A sixth mule carried two leather ammunition boxes, each containing eight bagged charges and eight shells (solid, shrapnel or case-shot). Performance with the standard 10.5lb shell included a muzzle velocity of about 1300 ft/sec and a maximum range of 5500 yards. It is believed that only 183 of the 10-pr jointed guns were ever made. Though the obturatorpad breech mechanism was an improvement, it and the bagged charge were obsolescent even as the gun was being introduced to service. Clamouring for a better design resulted in 1908 in the introduction of the 2.75-inch Gun, Breech-Loading, Mark I. This incorporated an improved form of the screw-breech, a hydrospring recoil suppressor, and a light metal shield; it also fired a 12.5lb shell.

The Indian Army mountain batteries that came to Europe in 191415 were all armed with the 10-pr jointed breech-loader, but the guns were immediately replaced with the 2.75-inch Gun BL Mk I. The unwanted 10-pr weapons were sent first to France and then, when nothing could be done with them, off to end their days in Egypt or Mesopotamia. Others remained in India into the 1920s.

We know that two six-gun batteries of 10-pr Ordnance, B.L., 10 pdr. Jointed were sold to the Nepalese government in 1924, part of a consignment that included five thousand SMLE rifles and 24 Vickers Guns. India Office papers in the British Library reveal that the guns were extensively refurbished at substantial cost to Nepal, and were accompanied by cordite cartridges, 5560 shrapnel shells, 240 common shell, 192 star shell, friction igniters, and a selection of time, percussion, and time and percussion fuzes. The Screw Guns were a mixed group containing some of the first to have been made (some surviving carriages are dated 1902) and a variety of later parts. Some of the breech-blocks bear the marks of the Royal Gun Factory and dates in the 19024 period; others, probably replacements, were apparently made in India, and a group dating from the First World War came from the Elswick Ordnance Company. A typical original hinge-piece is marked B.L. 10 PR. (Breech loading, 10-pounder) over R. G. F. (Royal Gun Factory, Woolwich) and the Pattern Mark, I over 1902 . What is apparently the sequential gun identifier makes a third line: for example, No 37. One of the breechblocks bears the number 2, another is 6. The later hinge-pieces are marked B.L. 10 PR 2.75 & 2.75. C. (possibly made in India), or B.L. 10 PR. 2.75 & 2.75 CONVD (also marked E. O. C. for the Elswick Ordnance Company, and dated 1917). Essentially similar legends will be found on the breech-block. Indian government property and inspectors marks (e.g., I I G with a Broad Arrow) are also often present. Most of the plates on the carriages indicate that they were made in the Royal Carriage Department, each also bearing a sequential number applied irrespective of the calibre and design of the accompanying gun.

The weights also vary slightly from carriage to carriage of the same type, depending on minor differences in materials and construction. Above: the descriptive plate attached to the carriage of a typical ex-Nepalese 10-pr mountain gun. It can also be seen on the left side of the carriage in the view below, which also shows the design of the wheel hub and the twelve wood spokes. Removing the chained wedge frees the wheel from the axle tree.

Fast Shipping with Professional Packaging

Thanks to our longstanding association with UPS FedEx DHL, and other major international carriers, we are able to provide a range of shipping options. Our warehouse staff is expertly trained and will wrap your products according to our exact and precise specifications. Prior to shipping, your goods will be thoroughly examined and securely secured. We ship to thousands clients each day across multiple countries. This shows how we're dedicated to be the largest retailer on the internet. Warehouses and distribution centres can be located throughout Europe as well as the USA.

Note: Orders with more than one item will be assigned a processing date depending on the item.

Before shipping before shipping, we'll conduct a thorough inspection of the items you have ordered. Today, the majority of orders will be delivered within 48 hours. The delivery time will be between 3-7 days.

Returns

The stock is dynamic and we cannot completely manage it because multiple stakeholders are involved, including our factory and warehouse. So the actual stock may alter at any time. It's possible that you may not receive your order once the order has been made.

Our policy is valid for a period of 30 days. If you don't receive the product within 30 days, we are not able to issue a refund or an exchange.

You can only return an item if it is unused and in the same state as the day you received it. You must have the item in its original packaging.

Related products

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Angolan Rebel 1970s era 60mm Inert Display Mortar from Angolan Civil War Original Items

Uncategorized

Uncategorized

Uncategorized

Australian WWII Owen MK1 Machine Carbine SMG Custom Fabricated Replica with Sling Original Items

Uncategorized

Band of Brothers ORIGINAL GERMAN WWII Le. F.H. 18 10.5cm ARTILLERY PIECE Original Items

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Armoured Fighting Vehicles of the World: AFVs of World War One (Hardcover Book) New Made Items

Uncategorized

Uncategorized

Uncategorized

Uncategorized