Original German WWII 1942 Dated Black Preßstoff & Leather Flare Signal Pistol Holster by Curt Vogel K.G. Original Items

$ 395,00 $ 118,50

Original Item: Only One Available. This is a lovely, service used example of the standard German WWII issue heavy black soft shell flare signal pistol holster, as used throughout the war. Unlike most however, this is actually made mostly of “Preßstoff”, an imitation leather made from pressed paper. The “hinge” for the lid is a strip of leather that is riveted onto the flap and body, as are the straps and buckle loops. Everything else is made from the pressed paper.

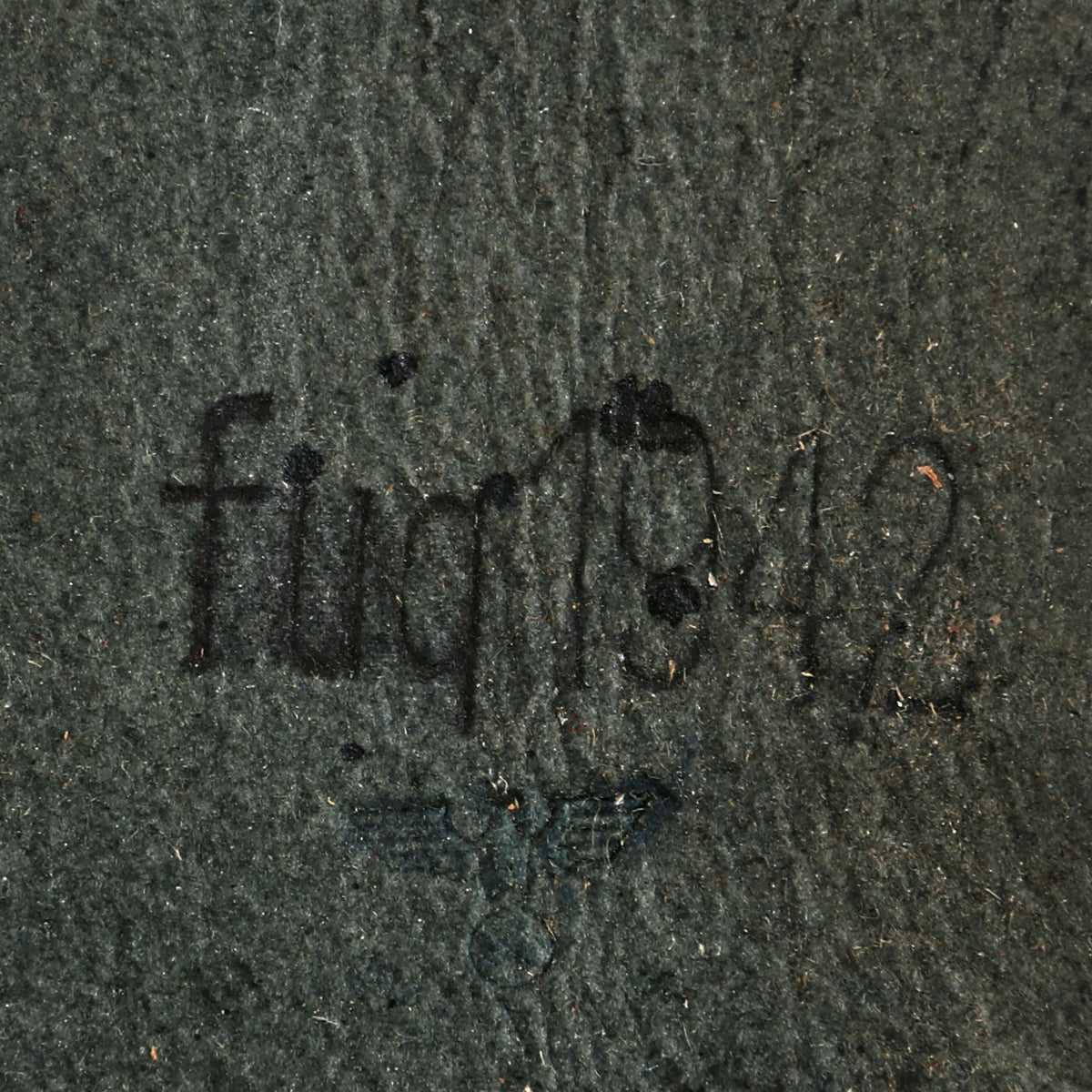

The holster definitely looks to have seen a good amount of use in service, and shows overall wear and wrinkling in the material. The finish is a bit worn, and the seams are a bit loose, as the black stitching has stretched over the decades. Everything is still intact and functional, and it is marked on the interior left bottom of the top flap with a faint fuq 1942, for manufacture by Cottbusser Lederwarenwerk Curt Vogel K.G. of Cotbuss, Germany. Below this is Waffenamt (Eagle) / WaA14, the correct inspector for this maker. The front closure is fully functional, as is the securing strap for the cleaning rod, though the latter does show some cracking. The cleaning rod is absent on this example.

The holster is complete and fully functional, and in lovely service used condition. This would be perfect for any WWII German Flare pistol that doesn’t have a nice home to live in. Ready to display!

Presstoff (also Preßstoff or Pressstoff) is the German-language term for a type of ersatz or artificial leather used during the first half of the 20th century. Made of specially layered and treated paper pulp, Presstoff was durable and easily adapted to be used in place of leather, which under wartime conditions was rationed. First invented in the 19th century, it gained its widest use in Germany during the Second World War.

Presstoff use included but was not limited to binoculars cases and straps, horse tack, bayonet frogs, equipment belts, cap visors etc. In short, Presstoff could be used in almost every application normally filled by leather, excepting items like footwear that were repeatedly subjected to flex wear and/or moisture. Under these conditions Presstoff tended to delaminate and lose cohesion.

Fast Shipping with Professional Packaging

Thanks to our longstanding association with UPS FedEx DHL, and other major international carriers, we are able to provide a range of shipping options. Our warehouse staff is expertly trained and will wrap your products according to our exact and precise specifications. Prior to shipping, your goods will be thoroughly examined and securely secured. We ship to thousands clients each day across multiple countries. This shows how we're dedicated to be the largest retailer on the internet. Warehouses and distribution centres can be located throughout Europe as well as the USA.

Note: Orders with more than one item will be assigned a processing date depending on the item.

Before shipping before shipping, we'll conduct a thorough inspection of the items you have ordered. Today, the majority of orders will be delivered within 48 hours. The delivery time will be between 3-7 days.

Returns

The stock is dynamic and we cannot completely manage it because multiple stakeholders are involved, including our factory and warehouse. So the actual stock may alter at any time. It's possible that you may not receive your order once the order has been made.

Our policy is valid for a period of 30 days. If you don't receive the product within 30 days, we are not able to issue a refund or an exchange.

You can only return an item if it is unused and in the same state as the day you received it. You must have the item in its original packaging.

Related products

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Angolan Rebel 1970s era 60mm Inert Display Mortar from Angolan Civil War Original Items

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Band of Brothers ORIGINAL GERMAN WWII Le. F.H. 18 10.5cm ARTILLERY PIECE Original Items

Uncategorized

Uncategorized

Uncategorized