Original German 1898 DWM Maxim Argentina Contract Display Machine Gun with Tripod Original Items

$ 10.995,00 $ 2.748,75

Original Item: Only One Available. This is an incredible and extremely rare example of an original Pre-WWI German made Maxim heavy machine gun manufactured in 1898! This is one of the most influential weapons of the 20th century that certainly belongs in an advanced Military or German arms collection.

This example is non-firing and inert. It conforms to BATF guidelines by a torch cutting, severing and removing a large section of the right side receiver plate. It has all original parts (with exception of two butterfly nuts on the tripod) with visible matching 140 serial numbers. The tripod folds but the elevation is frozen. Otherwise it is offered in exceptional all original condition (with a bit of new paint on the tripod legs).

Another 1898 Argentinian Contract DWM maxim which was a registered DEWAT sold in September 2012 for $34,500 and can be seen at this link.

This weapon was the first true self-sustaining machine gun that fired in a fully-automatic mode without any external means other than by power of the round and mechanism itself. This series of machine guns were developed by Hiram Maxim, in the 1883-1884 timeframe with the final design being finished in 1885 and was originally produced by the Spandau Arsenal as well as a series of other German companies and countries.

Maxim was a self taught engineer who demonstrated his design throughout Europe with the British Army being the first to make any notable purchases of this weapon and the first country to actually use this weapon in battle in Chitral India, the Sudan and again in the Boxer Rebellion in 1899. Germany officially adopted the weapon in 1899 and used it throughout WWI and well into the Weimar period.

The following is from “The Devils Paintbrush” by Dolf L. Goldsmith:

Argentina was a fairly early user of the Maxim, receiving 50 guns from Maxim Nordenfelt in 1895. These guns bore factory serial nos. 5537 – 5586 and were given Argentine Army nos. 1 – 50. They were supplied in the 7.65x53mm Belgian Mauser calibre. In 1898, the year the Maxim Nordenfelt “leash” agreement expired, about 130 guns (the bulk of a second, 150-gun Argentine order) were supplied by DWM directly. The remainder of the order, about 20 guns, followed in 1902, fitted with water Jackets and fusee spring covers made of steel. Thus while most South American countries adopted the Hotchkiss, even though they had previously tested the Maxim, by 1902 Argentina had 200 Maxim guns.

The Argentine Maxims made by Maxim Nordenfelt and DWM (except for DWM’s last 20 steel-jacketed guns, mentioned above) were identical in every respect, featuring full brass water jackets, the early crank and the 1889-style lock. They were mounted on the VSM “Acland” tripod (designed by Maxim’s so-called “Captain Calamity”, MNG&ACLs military liaison officer who among other things advised the British Army not to buy the Pom pom).

Argentinian Maxims were initially all sighted for the old round-nosed 7.65mm bullet, adopted by the Belgians in 1889 and the Argentinians in 1890, but in 1909 the guns were rebarreled and resighted to reflect the much flatter trajectory of the newly adopted ogival (pointed) 7.65mm bullet.

These guns remained in service until the 1960s, when they were replaced and sold. Many were subsequently destroyed, but some ended up in gun collections and museums in the U.S.A. and Canada. Only a few of the original 50 Maxim Nordenfelt guns are known to have survived. There are probably less than 10 MNG& ACL Maxims in the United States today.

As with most commercial purchasers, the Argentine Army wanted (and got) its own series of serial numbers: nos. 1 -50 from MNG&ACL in 1895, and nos. 51 – 200 from DWM 3 years later.

On the top cover of the 1898 Argentine model 1898 Maxim, originally the plate read ‘‘Cartucho Mauser Argentino 1891”’ but in 1909 Spitzer ammunition was adopted, and its much flatter trajectory necessitated the much shorter ear sight shown here. The old ‘1891’ was milled out on converted guns and ‘1909’ stamped in its place. As witness the original rear sight slot (ahead of the word ‘Argentino’), the improvement in trajectory was truly remarkable!

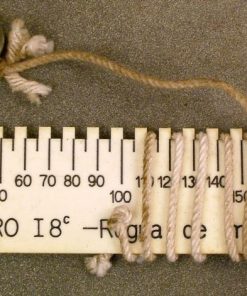

This is a DWM production model with serial number “140” (meaning it was the 89th made out of 130) that as far as we can tell has all externally matching serial numbers on every part, the receiver, barrel jacket, top cover, bolt and internal feed pawl mechanisms, back plate and the butterfly trigger mechanism. The left side brass fusse spring cover is marked “No.140 / MAXIM’S PATENT / 1898” surrounded by “DEUTSCHE WAFFEN – und MUNITIONS FABRIKEN – BERLIN“.

The left side of the receiver is fitted with an original base for a side mounted Carl Zeiss 2X Optical Sight (not included with this weapon). Interestingly enough, on the left side of the receiver is a round selection mechanism where the machine gunner could actually set the number of rounds the machine gun would shoot in a single bust. The settings range from single shot up to 70 rounds (in increments of 1 round) per burst. With the large distinctive brass water jacket around the barrel, which held seven quarts of water. These Maxims could fire approximately 500 rounds of sustained fire before the water started to boil and up to 2,000 rounds of sustained fire before the water would completely boil off. During WWI this weapon would reek havoc and devastation in the large open field battles in France and Germany where it would literally mow down hundreds of men charging the opposing forces and eventually was nicknamed the “Devils Paintbrush” because of the thousands of soldiers that it killed. This single weapon changed the tactics of land warfare forever. It is complete with original large ground mounted tripod, pintle with a T&E mechanism attached to the mount.

Argentina’s “World Standard” Maxim Machine Gun by Robert Segal

Argentina was an early user of the Maxim water-cooled machine gun, ultimately purchasing English and German made Maxims under three separate contracts. The first order was placed by Argentina’s Navy Purchasing Commission in 1895 for 50 World Standard Maxims manufactured by the Maxim Nordenfelt Guns and Ammunition Company Limited (MNG&ACL) in England. These first 50 guns were given Argentine serial numbers 1-50 and chambered in the 7.65×53 Belgium Mauser caliber. The nomenclature information on the fusee spring cover included the MNG&ACL information and the 1895 year of manufacture. In 1898 a second contract for the World Standard Maxim was placed, this time with Deutsche Waffen und Munitionsfabriken (DWM), a licensed Maxim manufacturer in Germany, from the Argentine Army Purchasing Commission for 130 guns still chambered for the Belgium Mauser 7.65×53 caliber. These guns were serially numbered 51-180. The DWM nomenclature information on the fusee spring cover included the 1898 year of manufacture. The third and final contract signed in 1900 brought in another 20 World Standard Maxims from DWM and were serial numbered 181-200. All of these World Standard Maxims had brass water jackets and brass fusee spring covers except for the last twenty DWM guns, which were fitted with steel water jackets and fusee spring covers. Interestingly, most South American countries adopted the French Hotchkiss machine gun, yet Argentina had 200 of these early Maxims in their inventory.

Beautifully made with its water jacket, feed block, fusee spring cover, receiver floor plate and rear grip plate made of brass, the World Standard Maxim Models, often just called “Brass Maxims,” were a stunning, and lethal, piece of the firearm maker’s craft that was also esthetically pleasing to the eye. These guns had the early straight style of crank handle, an 1889 style lock and wooden roller belt assist located within the brass feed block. The gun is mounted on an Acland tripod that can be mounted on a wheeled field carriage.

All 200 of Argentina’s Maxims were originally chambered in the 7.65x53mm 1891 Belgium Mauser caliber and the long sight bar affixed to the upper receiver was calibrated for this heavy, round-nosed, high trajectory bullet. Each gun was fitted with a brass data plate on the top cover over the feed block reading, “Cartucho Mauser Argentino 1891” indicating the use of the 1891 Mauser cartridge. In 1909, Argentina adopted the new 7.65x53mm Spitzer round with the pointed bullet and flatter trajectory. All of Argentina’s Maxims were then sent back to DWM to be rebarreled for the new cartridge, have the long rear sight bar shortened to match the high-speed, flatter trajectory of the new cartridge, an optical sight bracket was attached to the left side of the receiver for attaching a commercially made 2×12 optical sight made by Carl Zeiss of Jena, Germany (that also fit the Swiss Maxim MG11), and provision was made also on the left side of the receiver for a removable shoulder brace made of steel and wood. The original brass cartridge data plate riveted to the top cover over the feed block had the “1891” milled out and “1909” engraved in its place to reflect the updates and change in cartridge use.

Though well equipped, Argentina did not participate in any major conflicts during the period that the Maxims were in their military inventory up to 1929. After that, they were given over to the police where they remained until 1959 when they were declared obsolete and sold.

It wasn’t until the turn of the century that Maxim water jackets were made of steel rather than brass. While there were many brass-jacketed Maxims made and sold around the world in the 1880s and 1890s, very few made it into the U.S. at the time and of course can’t be imported in now. Thus, these early brass Maxims of any vintage or type are rare in the U.S. and highly desired by collectors. To our good fortune, Sam Cummings of Interarmco in Alexandria, Virginia was able to import 91 of the guns into the United States in 1960. Those that remained in Argentina were used to decorate various officers’ clubs, donated to museums or sold to Argentine collectors. Of the 91 guns imported into the U.S., 8 were exported, 28 ended up in government custody for museums, storage or destruction, and the remaining 55 are now mostly owned by collectors.

Maxim Operating System

The Maxim operating system used in the World Standard is the basic operating principle employed in all Maxim guns. The gunner inserts the tab of a loaded cartridge belt into the feed block from the right, pulling it to the left, until it is secured by the belt holding feed pawls. The gunner then manually pushes the crank handle forward and holds it there while pulling on the protruding end of the belt, then releases the crank handle to return to the rear under spring tension. This allows the extractor on the T-slot to grip the first round in the belt. The gun is now in the “half load” position. Rotating the crank handle forward again, pull the cartridge belt tab once more to the left and let the crank handle fly back under its spring tension. The gun in now loaded with a cartridge in the chamber and is ready to fire.

Upon pressing the trigger, that actuates the trigger bar releasing the sear; the firing pin is released and goes forward igniting the cartridge driving the bullet down the barrel. The barrel and the bolt are securely locked at this point. After recoiling three-quarters of an inch, the bolt is unlocked and the crank engages the unlocking cam, breaking the toggle joint and freeing the bolt. The recoiling forces are now able to accelerate the bolt assembly to the rear and rotate the crank. This winds the actuating chain, loading the extension-type driving spring while the recoiling mechanism completes its rearward stroke.

After unlocking of the bolt from the barrel, the sliding boltface (T-slot) begins simultaneous extraction of the empty case from the chamber and withdrawal of a loaded round from the belt. Continued rearward movement engages cams in the receiver to force the sliding boltface downward, bringing the loaded round in line with the chamber and the empty case in position for the ejection tube.

Also during recoil, a cam lever action moves the entire feed block slide to the right. The top feed pawls move over to engage the incoming round in the belt, at the same time compressing the barrel return spring. After completing its full recoil stroke, the forward action of the barrel and barrel extension returns the feed block slide to the left, bringing the next live round in the belt into position against the cartridge stops for engagement by the sliding T-slot.

The complete force of recoil having expended itself, the extended driving spring starts the movement of counter recoil. As the bolt moves forward, the cartridge to be fired is positioned for chambering. When this happens, the T-slot rises, “wipes” itself clear of the spent case and slips over the rim of the incoming round in the belt.

When the bolt has reached its extreme travel forward, the toggle joint is forced slightly below the horizontal by the connecting rod. At this securely locked position the sear is depressed and disengaged from the firing pin, removing the safety feature, so that continued pressure on the trigger permits full automatic fire.

What’s in a Name?

Question: Which of the following is the proper name for the Argentine brass Maxim?

Model of 1895;

Model of 1898,

Model of 1909.

Answer: None of the above.

It is common and convenient among collectors and other interested parties to refer to Maxims as relating to a “model” number based upon the year of manufacture that is typically stamped on the fusee spring cover as part of the manufacturer’s nomenclature. While this is actually quite helpful, this is in fact, technically, incorrect. While the military may designate a model number (German MG 08, Swiss MG 11, U.S. Model of 1904, etc., usually based upon the year of adoption for service), Maxim in England, and all the other licensed Maxim manufacturers, did not use model numbers for their commercial sales.

Maxim’s first guns dating from 1884 to 1887 were really hand-made prototype affairs. As sales increased during this time period, so did the learning curve experience in manufacturing techniques and methods, operational efficiencies, weight and material used to make his product better. Outgrowing his little shop in London due to increasing sales, Maxim merged with the Nordenfelt Gun Company, which greatly expanded his production capabilities and Maxim was able to then incorporate his improvements on a production line scale. Every bit the salesman he was, Maxim named his guns the World Standard in 1888 as a marketing tool to imply the epitome of firearm development in his sales presentations and literature. (The name World Standard was never marked on the guns themselves.) Thus, a Maxim produced after 1888 is properly called a World Standard with the year of manufacture being noted as an aside. As years progressed and further improvements were made in the lock, feed block, crank handle, etc., these advancements can fortunately be tracked as the production or contract years are duly noted on the guns. So while a gun produced in 1898 may have certain features not present on guns produced in 1895, they are both correctly just called World Standard. The same holds true for the 1909 date as that appears on the top cover brass plate on the Argentine contract guns. The year designation helps determine what improvements can be expected to be found on the gun. The shorthand for this in the collector’s world is to call it as a model number. All these dates properly place the weapon in a linear time line, and are convenient in noting the introduction of certain product improvements.

Fast Shipping with Professional Packaging

Thanks to our longstanding association with UPS FedEx DHL, and other major international carriers, we are able to provide a range of shipping options. Our warehouse staff is expertly trained and will wrap your products according to our exact and precise specifications. Prior to shipping, your goods will be thoroughly examined and securely secured. We ship to thousands clients each day across multiple countries. This shows how we're dedicated to be the largest retailer on the internet. Warehouses and distribution centres can be located throughout Europe as well as the USA.

Note: Orders with more than one item will be assigned a processing date depending on the item.

Before shipping before shipping, we'll conduct a thorough inspection of the items you have ordered. Today, the majority of orders will be delivered within 48 hours. The delivery time will be between 3-7 days.

Returns

The stock is dynamic and we cannot completely manage it because multiple stakeholders are involved, including our factory and warehouse. So the actual stock may alter at any time. It's possible that you may not receive your order once the order has been made.

Our policy is valid for a period of 30 days. If you don't receive the product within 30 days, we are not able to issue a refund or an exchange.

You can only return an item if it is unused and in the same state as the day you received it. You must have the item in its original packaging.

Related products

Uncategorized

Uncategorized

Australian WWII Owen MK1 Machine Carbine SMG Custom Fabricated Replica with Sling Original Items

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Armoured Fighting Vehicles of the World: AFVs of World War One (Hardcover Book) New Made Items

Uncategorized

Uncategorized

Band of Brothers ORIGINAL GERMAN WWII Le. F.H. 18 10.5cm ARTILLERY PIECE Original Items

Uncategorized

Angolan Rebel 1970s era 60mm Inert Display Mortar from Angolan Civil War Original Items

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized