Original French WWI Inert P1 Pear / Spoon Percussion Grenade – Percutante Grenade Nr.1 Original Items

$ 495,00 $ 148,50

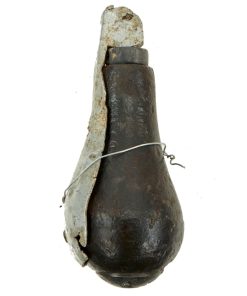

Original Item: Only One Available. This is totally inert BATF compliant genuine World War One French Grenade Percutante n°1 (Percussion Grenade Nr. 1). These are quite hard to find, and this is the second example that we have had. These were called both the “Pear” grenade due to the shape, as well as the “Spoon” grenade due to the large arming device for the ignition system.

This example has an intact body, lead bottom cap, fuze bolster, and a partial “spoon”. This would normally be connected to the fuze assembly at the top, but this is missing.

A great example of a very hard to find French WWI grenade!

As early as the 17th century, virtually every grenade design, regardless of the fuze, had one fundamental flaw. Any wick type fuze, if not consumed completely by the time it reached the target, meant the grenade could be thrown away, sometimes right at the original thrower, definitely not an optimal outcome. The idea of an impact detonated grenade is there fore pretty old, but its design met a lot of complex problems that were far from being perfectly solved in 1914 by any country.

At the beginning of the war, the French Army used artisanal percussion ‘bangers’, as well as Aasen grenades, from the name of that Danish inventor who was selling the same grenades to the Germans. However, none of these solutions were satisfactory.

However in May 1915, the French soldiers finally received a brand new grenade: the P1 (percutante n°1) percussion grenade, designed and made in France by Billant, who also invented the M1916 automatic lever grenade igniters.

This new weapon was almost immediately nicknamed ‘Pear grenade’ or ‘Spoon grenade’ by the fighters, for somewhat obvious reasons. The grenade was made of a pig iron body with inner fragmentation grooves, closed at its base by a lead plug, and on the top was the igniter. This mechanism was composed of a detonator triggered by a starter that was hit by a moving percussion pin when the grenade landed vertically on its base. This percussion movement was only possible when the spoon-like safety lever was up. A security wire wrapping the spoon lever and the grenade body at rest had to be cut prior to launching the grenade, so that the rotation of the lever was possible.

Unwanted arming of the grenades by rupture of this wire and movement of the aluminum or steel spoon lever caused numerous accidents. Moreover, the design’s requirement of having the grenade landing vertically on its base was problematic as well. The pear shape was supposed to help with this, as was a piece of fabric under the spoon that served as a tail in flight. Despite these two precautions, the results were rather uncertain.

With the dangerous and unreliable ignition system and often poor results from fragmentation, this grenade was hardly a “success”, but was nevertheless made in large numbers. The danger they posed during disarming and storage is why they are so scarce on the market today.

Fast Shipping with Professional Packaging

Thanks to our longstanding association with UPS FedEx DHL, and other major international carriers, we are able to provide a range of shipping options. Our warehouse staff is expertly trained and will wrap your products according to our exact and precise specifications. Prior to shipping, your goods will be thoroughly examined and securely secured. We ship to thousands clients each day across multiple countries. This shows how we're dedicated to be the largest retailer on the internet. Warehouses and distribution centres can be located throughout Europe as well as the USA.

Note: Orders with more than one item will be assigned a processing date depending on the item.

Before shipping before shipping, we'll conduct a thorough inspection of the items you have ordered. Today, the majority of orders will be delivered within 48 hours. The delivery time will be between 3-7 days.

Returns

The stock is dynamic and we cannot completely manage it because multiple stakeholders are involved, including our factory and warehouse. So the actual stock may alter at any time. It's possible that you may not receive your order once the order has been made.

Our policy is valid for a period of 30 days. If you don't receive the product within 30 days, we are not able to issue a refund or an exchange.

You can only return an item if it is unused and in the same state as the day you received it. You must have the item in its original packaging.

Related products

Uncategorized

Band of Brothers ORIGINAL GERMAN WWII Le. F.H. 18 10.5cm ARTILLERY PIECE Original Items

Uncategorized

Uncategorized

Australian WWII Owen MK1 Machine Carbine SMG Custom Fabricated Replica with Sling Original Items

Uncategorized

Uncategorized

Angolan Rebel 1970s era 60mm Inert Display Mortar from Angolan Civil War Original Items

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized