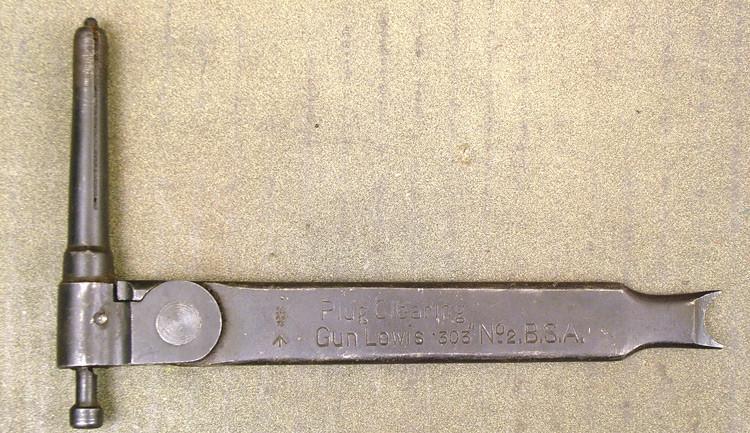

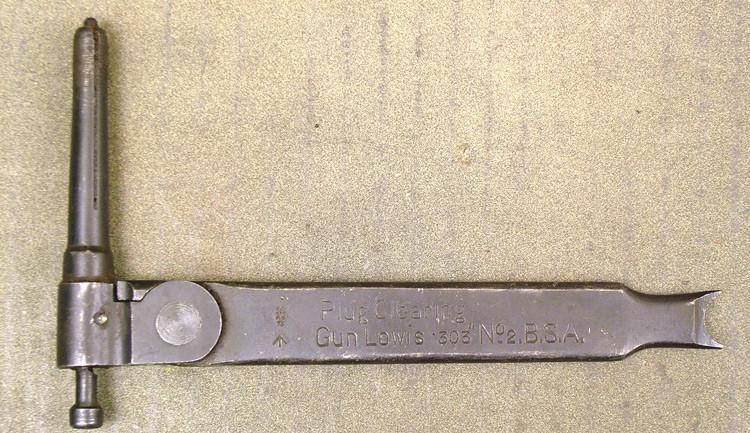

British Lewis LMG Clearing Plug: No. 2 Original Items

$ 69,95 $ 34,98

Original Item: In British nomenclature, this was referred to as a ?clearing plug.? If a cartridge case ruptured, leaving the forward part of the case in the barrel chamber, this tool was inserted into the chamber and the stud extending from the elbow of the tool was tapped forward. This caused the machined ridges on the exterior of the tool to grab the broken shell from the inside. The handle of the clearing plug was then rotated forward, levering the broken case out of the chamber. After many clearing plugs had been manufactured, a directive was issued to modify them to permit use as a stuck cartridge tool. The end of the handle was curved and machined to provide a grip for the rim of the .303 cartridge. The modified clearing plug was identified as the No. 2, and the unmodified tool became the No. 1. At the same time, newly made clearing plugs were manufactured with the stuck case tool in the handle. These were also identified as No. 2. Consequently, there are three general variations of the tool:

1. The original clearing plug with unmodified handle.

2. The original clearing plug modified to include the stuck case tool.

3. Newly made clearing plugs with the stuck case tool built in.

Examining the markings on variations 2 and 3 of the tool will indicate whether the tool was modified from the original configuration (No. 1) or was newly manufactured as a No. 2.

This is the No.2 (NOT modified from N0.1 but manufactured as a No.2)

Prompt Shipping and Professional Packaging

We provide a variety of shipping options due to our long-running partnerships with UPS, FedEx and DHL. Our warehouse personnel are well trained and will pack the goods according to our exact and precise specifications. Before shipping your items will be thoroughly inspected and secured. Every day, we deliver to thousands of customers in different countries. This is a sign of our determination to become the largest online retailer worldwide. Both Europe as well as the USA have warehouses and distribution centers.

Note that orders containing more than one item will be subject to a processing period that is based to the particular item.

Prior to shipping the items, our staff will carry out an exhaustive inspection of the products you ordered. Today, most orders will be delivered within 48 hours. The estimated delivery time is between 3-7 days.

Returns

The stock is constantly changing. It's not entirely managed by us since we are involved with multiple entities, including the factory and our storage. Therefore, the actual inventory could alter at any time. It is possible that you will not receive your order after the order has been made.

The period of time is 30 days. Unfortunately, if 30 days have passed since you purchased your product, we are unable to provide a refund or exchange.

The item must not be in use and must be in the original packaging. The item must be in the original packaging.

Related products

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Australian WWII Owen MK1 Machine Carbine SMG Custom Fabricated Replica with Sling Original Items

Uncategorized

Armored Burgonet Helmet & Polearm from Scottish Castle Leith Hall Circa 1700 Original Items

Uncategorized