Original German WWII Luftschutz Civil Air Defense Beaded M40 Helmet Liner & Damaged Chinstrap – Q64 Original Items

$ 550,00 $ 165,00

Original Item: Only One Available. This is a very good condition example of a somewhat rare genuine steel construction M40 “Beaded” Third Reich helmet, outfitted for German WWII Luftschutz Civil Air Defense use. These helmets were essentially like the Military issue, however the steel was not as thick or as high quality. They were given a “bead” around the edge, to avoid mixing them up with the military version.

The exterior of this German helmet retains close to 100% of the original dark blue paint, with some scuffing and light overall wear. There is one area on the left where the paint is scraped away, but this is one of the best examples of a Beaded M40 Luftschutz shell we have ever seen. The Luftschutz decal is clean and about 95% complete, with only a few small areas having flaked away. There is a bit of deterioration of the enamel layer of the decal, which has made it a bit darker and gives it a great aged look.

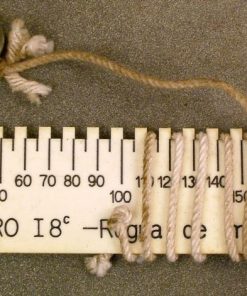

Comes with complete liner, which looks to be made from Preßstoff faux leather, made from layers of pressed paper. All three double cork washers are still intact with all three split pins present, and retaining almost all of their paint. The liner does have some wear, but it is still soft and does not show much in the way of deterioration. The fingers are all present, however the intact top tie has torn through the ends of two of them. The chinstrap is present, however the securing rivet for the buckle tore free along with some of the leather, so the buckle is no longer secured to the leather.

The reverse, interior, neck guard apron is serial number stamped 478 and the interior, left side, apron has the stamped manufacturer’s code and size, Q64 indicating that it was manufactured by Quist in the German city of Esslingen. Size 64 is a nice smaller size that can accommodate liners from 56cm to 57cm or US 7 to 7 1/8. Size 64 shells are harder to find and are therefore more valuable to a collector.

M40 Beaded Luftschutz helmets are one of the rarer varieties of the Luftschutz style and hard to find. This is a very good example, and sure to appreciate in value over the years.

Formed in late 1932 the Deutsches Luftschutzverband, (German Air Protection League), was a voluntary organization designed to provide civil air raid protection in large civilian centers. Shortly after AH ascension to power the Deutsches Luftschutzverband was restructured and placed under the supervision of the Reichsluftfahrtministerium, (National Air Ministry), under the control of Hermann Göring. On April 29TH 1933 the Deutsches Luftschutzverband was renamed RLB, Reichs Luftschutz Bund, (National Air Raid Protection League) and was given status as an official national organization tasked with all aspects of civil air raid defence. The RLB remained a voluntary organization with a small cadre of paid, full-time uniformed officials to oversee the organizations functions until June 1935 when obligatory service was introduced. Only the most basic uniform and equipment items were supplied to the cadre personnel, with the rest having to be bought personally by members. On September 26TH 1938 a specific helmet for RLB personnel was introduced that incorporated a raised horizontal “bead” between the visors and crown. These helmets commonly called the “Gladiator” style were supplemented with M35, M40 and M42 helmets that also incorporated a raised horizontal “bead” between the visors and crown. The Luftschutz also utilized a variety of captured helmets.

Presstoff (also Preßstoff or Pressstoff) is the German-language term for a type of ersatz or artificial leather used during the first half of the 20th century. Made of specially layered and treated paper pulp, Presstoff was durable and easily adapted to be used in place of leather, which under wartime conditions was rationed. First invented in the 19th century, it gained its widest use in Germany during the Second World War.

Presstoff use included but was not limited to binoculars cases and straps, horse tack, bayonet frogs, equipment belts, cap visors etc. In short, Presstoff could be used in almost every application normally filled by leather, excepting items like footwear that were repeatedly subjected to flex wear and/or moisture. Under these conditions Presstoff tended to delaminate and lose cohesion.

Fast Shipping with Professional Packaging

Thanks to our longstanding association with UPS FedEx DHL, and other major international carriers, we are able to provide a range of shipping options. Our warehouse staff is expertly trained and will wrap your products according to our exact and precise specifications. Prior to shipping, your goods will be thoroughly examined and securely secured. We ship to thousands clients each day across multiple countries. This shows how we're dedicated to be the largest retailer on the internet. Warehouses and distribution centres can be located throughout Europe as well as the USA.

Note: Orders with more than one item will be assigned a processing date depending on the item.

Before shipping before shipping, we'll conduct a thorough inspection of the items you have ordered. Today, the majority of orders will be delivered within 48 hours. The delivery time will be between 3-7 days.

Returns

The stock is dynamic and we cannot completely manage it because multiple stakeholders are involved, including our factory and warehouse. So the actual stock may alter at any time. It's possible that you may not receive your order once the order has been made.

Our policy is valid for a period of 30 days. If you don't receive the product within 30 days, we are not able to issue a refund or an exchange.

You can only return an item if it is unused and in the same state as the day you received it. You must have the item in its original packaging.

Related products

Uncategorized

Armoured Fighting Vehicles of the World: AFVs of World War One (Hardcover Book) New Made Items

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Australian WWII Owen MK1 Machine Carbine SMG Custom Fabricated Replica with Sling Original Items

Uncategorized

Uncategorized

Angolan Rebel 1970s era 60mm Inert Display Mortar from Angolan Civil War Original Items

Uncategorized

Uncategorized

Uncategorized

Uncategorized